You can change your home with customized household items using additive manufacturing. 3D printing has made it easy to solve everyday problems in creative ways.

If you love tech or want to make your home better, you can make things that fit just right. You can make kitchen tools, storage, and even parts for things you already have. For more ideas, check out this resource on what you can print.

Key Takeaways

- Create customized household items using additive manufacturing.

- Explore various applications, including kitchen tools and storage solutions.

- Use 3D printing to create replacement parts for household items.

- Personalize your home decor with unique, printed objects.

- Discover more possibilities for 3D printing in home improvement.

The Evolution of 3D Printing Technology

3D printing has changed a lot over the years. It started as a pricey industrial tool and now it’s for hobbyists and pros. 3D printing was first made in 1984 by Charles Hull. He created stereolithography, a way to make 3D objects from digital files.

From Industrial Applications to Desktop Solutions

At first, 3D printing was only for big companies and research places. It was used for rapid prototyping and making complex parts. But, it was expensive and hard to use. Now, we have cheaper and easier-to-use desktop 3D printers.

How Modern 3D Printers Work

Today’s 3D printers make things by layering materials like plastics, metals, and ceramics. They use 3D modeling software to guide them. This way, they can make shapes that are hard or impossible to make with old methods.

The Democratization of Manufacturing

The growth of 3D printing has made making things more accessible. Now, people and small businesses can make custom parts and products. This change has brought new chances for creativity and starting businesses.

Getting Started with Home 3D Printing

Starting your home 3D printing journey needs careful thought. You must understand the tech, the gear, and the materials. Home 3D printing lets you make custom manufacturing in your own home, a form of digital fabrication.

Choosing the Right 3D Printer for Your Needs

Finding the right 3D printer is the first step. Think about the projects you want to do, the space you have, and your budget. Look into different models, what they can do, and the support they offer.

Essential Tools and Materials

After getting your 3D printer, you’ll need the right tools and materials. You’ll need filaments like PLA, ABS, and PETG, and tools for finishing your prints. Knowing how different materials work is key for good prints.

Setting Up Your First Print Station

Setting up your first print station is more than just unpacking. You’ll need to calibrate your printer, get your designs ready, and make sure your space is safe and efficient. If you can’t get a 3D printer or need help, working with a good 3D printing company is a smart move.

By following these steps, you’ll be ready to start your home 3D printing journey. You’ll be able to make all sorts of things, from prototypes to everyday items.

Understanding 3D Printing Materials

3D printing is amazing because it can use many materials. This includes common plastics and advanced metals for advanced manufacturing. This means you can make prototypes and final products in many ways.

When you start with 3D printing, knowing the materials is key. The material you choose affects how strong, useful, and good-looking your prints will be.

Common Filament Types: PLA, ABS, PETG

PLA, ABS, and PETG are the most used materials in 3D printing. Each has its own special qualities and uses.

- PLA (Polylactic Acid): It’s biodegradable and made from renewable resources. It’s easy to print with and doesn’t warp much.

- ABS (Acrylonitrile Butadiene Styrene): This is a strong, impact-resistant plastic. It’s used in many products but needs a heated bed to print.

- PETG (Polyethylene Terephthalate Glycol): It’s strong and flexible. It’s a mix of PLA and ABS, making it easy to print and durable.

Specialty Materials for Specific Applications

There are also specialty materials for certain needs. These include:

| Material | Properties | Applications |

|---|---|---|

| Metal-filled filaments | Strong, durable, and can be sanded and painted | Functional parts, decorative items |

| Conductive filaments | Electrically conductive | Electronic components, circuits |

| Flexible filaments | Elastic, resistant to impact | Flexible parts, wearable items |

For more info on 3D printing materials, check out 3D Printing UK. They have a detailed guide for beginners.

Material Selection Based on Project Requirements

Choosing the right material for your project depends on several things. These include what the object will be used for, how durable it needs to be, and how it should look. Knowing about different materials helps you make the best choice for your project.

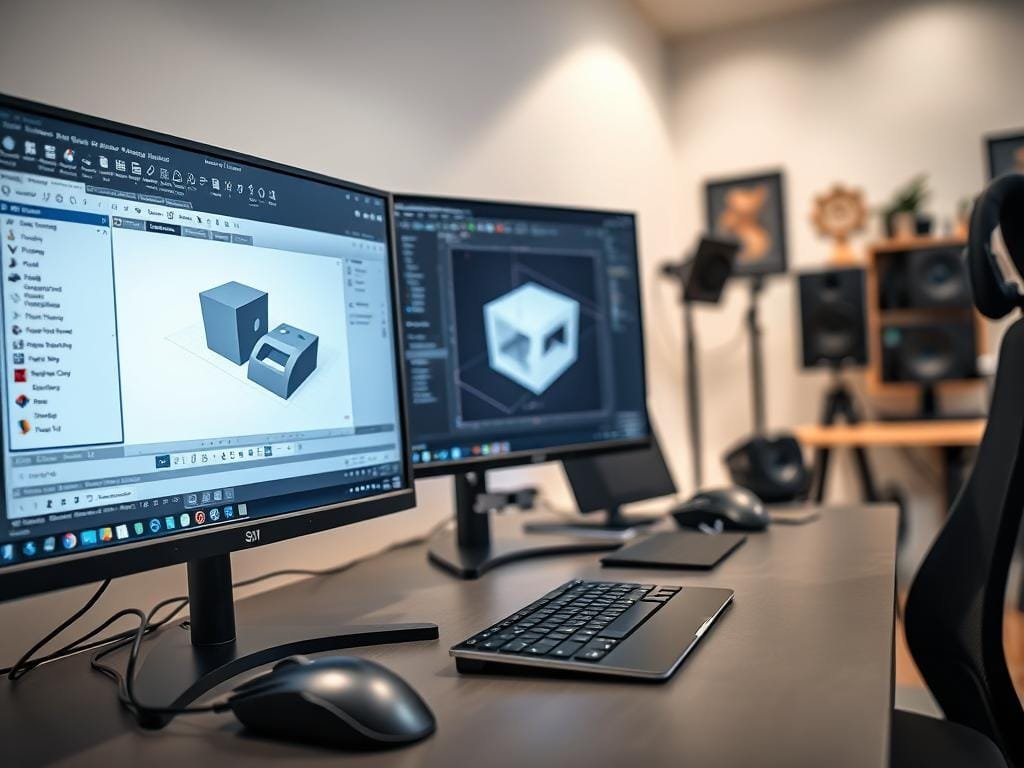

Mastering 3D Modeling Software

Getting into desktop 3D printing means learning 3D modeling software. It’s key to making your ideas real, from useful items to decorations.

Beginner-Friendly Design Tools

For newbies, there are easy-to-use design tools. Tinkercad and Fusion 360 have simple interfaces. They’re great for learning the basics of 3D design.

Intermediate and Advanced Software Options

When you get better, you’ll need more advanced tools. Blender and SolidWorks have lots of features for complex designs. They’re used in many fields, like engineering and animation.

Step-by-Step Guide to Creating Your First 3D Model

To make your first 3D model, pick a beginner-friendly software. Here’s how:

- Open your chosen software and get to know the interface.

- Begin with a simple shape, like a cube or a cylinder.

- Use the software’s tools to change the shape as needed.

- Save your model and export it in a format your 3D printer can use.

Resources for Learning 3D Modeling

There are many online resources for learning 3D modeling. YouTube, Udemy, and Coursera have tutorials and courses. Software providers also have guides and forums for help.

Learning 3D modeling software lets you use your desktop 3D printer fully. You can make lots of items for your home.

The 3D Printing Process: From Digital Design to Physical Object

3D printing turns digital designs into real objects. It involves several steps, from preparing the digital model to printing the final object.

Preparing Your 3D Model for Printing

First, your digital 3D model needs to be ready. Check it for errors, make sure it’s watertight, and adjust its size. Use 3D modeling tools for these adjustments.

Slicing Software and Optimal Print Settings

Next, use slicing software to break your 3D model into layers. This software lets you tweak settings like layer height and infill density. The right settings depend on your project and printer type.

Monitoring and Troubleshooting During Printing

Keep an eye on the print for any problems. Issues like adhesion and warping can happen. Quick troubleshooting saves time and material.

First Print Tutorial: A Simple Household Item

Start with a simple item like a phone holder or small container. These projects are perfect for beginners. They help you understand your printer’s strengths and weaknesses.

| Step | Description | Tips |

|---|---|---|

| 1. Model Preparation | Check and adjust your 3D model | Use software to ensure the model is watertight |

| 2. Slicing | Convert the model into printable layers | Adjust settings like layer height and infill density |

| 3. Printing | Monitor the printing process | Be ready to troubleshoot common issues |

Practical Household Items You Can 3D Print Today

3D printing lets you make many useful items for your home. You can design them to fit your needs and style. This way, your home can become truly yours.

Kitchen and Dining Solutions

You can print kitchen tools and gadgets like customized utensil holders and innovative spice racks. Even appliance parts can be printed. For example, a holder for your stand mixer can keep your kitchen tidy.

Organization and Storage Innovations

3D printing helps you make custom storage solutions. You can print bins, cable organizers, and shelf dividers. These fit your home’s layout and your style.

Bathroom and Utility Upgrades

In the bathroom, you can print practical items like soap dispensers and toothbrush holders. You can also make customized shower caddies. These items can match your bathroom’s look, adding a personal touch.

Decorative and Personalized Home Accents

3D printing also lets you make decorative items for your home. You can print customized vases, wall art, and more. These items can make your home truly unique.

| Category | Examples of 3D Printed Items |

|---|---|

| Kitchen | Utensil holders, spice racks, replacement appliance parts |

| Organization | Storage bins, cable organizers, shelf dividers |

| Bathroom | Soap dispensers, toothbrush holders, shower caddies |

| Decorative | Customized vases, wall art, personalized decorative accents |

With custom manufacturing and digital fabrication from 3D printing, you can make your ideas real. Your home will be more functional and personal.

Advanced 3D Printing Techniques for Home Projects

Exploring 3D printing can open up new possibilities for your home projects. Advanced manufacturing has made these advanced techniques more accessible. Now, residents can create complex items with ease.

Multi-Material and Multi-Color Printing

Printing with multiple materials and colors is a game-changer. It lets you make objects with different textures and looks. Imagine printing a vase with detailed designs or a functional item with various materials.

- Benefits: Enhanced aesthetics, improved functionality, and complex geometries.

- Applications: Decorative items, functional household goods, and customized parts.

Post-Processing Methods to Enhance Your Prints

Post-processing is key to getting your prints just right. Techniques like sanding, painting, and applying coatings can greatly improve your prints. For example, a waterproof coating can make a decorative fountain or planter more practical.

- Sanding to smooth out rough edges

- Painting to add color and detail

- Applying coatings for durability and water resistance

Combining 3D Printed Parts with Other Materials

Mixing 3D printed parts with other materials leads to innovative creations. This method uses the best of different materials, like fabric’s flexibility and metal’s durability. For example, you can 3D print a frame and add glass or wood for a unique piece of furniture.

Example: Making a lamp with a 3D printed base and a wooden shade.

Tutorial: Creating a Multi-Component Household Item

This tutorial will show you how to make a customizable storage box. You’ll learn to design, print, and assemble parts. Then, you’ll combine them with other materials for a stylish storage solution.

- Design the components using 3D modeling software

- Print the parts using multi-material 3D printing

- Assemble and post-process the final product

Troubleshooting Common 3D Printing Issues

Whether you’re new or experienced, 3D printing can have its hitches. But, knowing how to fix them can greatly improve your experience. As desktop 3D printing grows, learning to solve common problems is vital for a smooth process.

Print Quality Problems and Solutions

Print quality issues can vary, from layer adhesion to wrong sizes. To fix these, adjust your printer’s settings, use high-quality filament, and tweak your slicing options.

- Layer adhesion issues: Check temperature settings and ensure the bed is level.

- Inaccurate dimensions: Verify scaling factors in your slicing software.

Mechanical and Hardware Challenges

Mechanical problems often come from worn-out or misaligned parts. Keeping your printer well-maintained, like lubricating parts and checking belt tension, can help avoid many issues.

Software and Design-Related Issues

Software problems can arise from file format issues or wrong export settings. Make sure your 3D model is well-designed and exported correctly to avoid many issues.

Maintenance Tips for Longevity of Your 3D Printer

Regular upkeep is essential for your 3D printer’s longevity. This includes cleaning it, updating the firmware, and replacing old parts.

Conclusion: The Future of Home 3D Printing

3D printing is changing how we make household items. It lets us create custom storage, home decor, and more. With industrial 3D printing, homes can be built in hours, not months.

The future of home 3D printing is huge. We can make strong, cheap homes that can handle bad weather. We can also make custom items that help the planet. As 3D printing gets better, we’ll see even more cool uses at home.

You can start using 3D printing at home today. Make useful items that make your space better. With 3D printing getting easier to use, the future is looking great. It’s an exciting time to join this revolution.

FAQ

What is 3D printing, and how does it work?

3D printing, also known as additive manufacturing, creates objects from digital designs. It uses materials like plastics, metals, and ceramics. Modern 3D printers build objects layer by layer, following a digital file.

What are the benefits of using 3D printing for household items?

3D printing lets you make custom items that might not be available or too pricey. It also helps in repairing or replacing parts, reducing waste and promoting sustainability.

What kind of 3D printing materials can I use for household items?

You can use materials like PLA, ABS, PETG, and specialty filaments. These depend on what you need, such as durability or look.

How do I choose the right 3D printer for my needs?

Think about your projects, budget, precision needs, and material preferences. Research and compare different models to find the best one for you.

What is 3D modeling software, and how do I use it?

3D modeling software helps create digital designs for printing. Start with easy tools like Tinkercad or Fusion 360. Then, move to more advanced ones as you get better.

How do I troubleshoot common 3D printing issues?

First, identify the problem. Then, look for solutions online, like forums or tutorials. Common issues include print quality, mechanical, and software problems.

Can I use 3D printing to create complex or multi-component household items?

Yes, advanced techniques like multi-material printing can help. You can also use post-processing and combine parts with other materials.

How do I maintain my 3D printer to ensure its longevity?

Clean and lubricate your printer regularly. Check for worn parts and update software and firmware. This keeps your printer running well.